Laboratories are dangerous places to work. Many of the materials or chemicals that you come into contact with on a daily basis are potentially harmful to your health, and to the health of your co-workers if handled in a careless or incorrect manner. For this reason, it is vital to ensure that all the risks and potential hazards that could occur in this environment are clearly labelled.

Within our comprehensive range of safety signs and labels you will find a variety of labels, tapes and signs that are designed specifically for the identification of hazards within laboratories. Now, we know that time is precious, and it is very likely that you don’t have the time to search through our extensive range of labels and signs to find the signs that are relevant to your business...so we've done the searching for you! Below you will find a list of the most popular product categories for laboratories:

Laboratory Safety Labels & Tapes

Working in a laboratory means that you are often surrounded by biological hazards and infectious diseases. We have dedicated a whole section of our website to signs that have been specifically designed to raise awareness of such hazards and help to minimise the risk of infection.

In this department you will not only find various warning signs and labels, but we also offer a range of tapes that can be used to alert co-workers, visitors, couriers and even emergency services to the dangers present in your lab.

To view our full range of Laboratory Safety Labels & Tapes, please click here.

General Health & Safety Signs

When you are handling dangerous chemicals and materials, it is incredibly important to wear the correct PPE (Personal Protection Equipment) and wash your hands after handling certain objects. In our General Health and Safety Sign department, you will discover a range of signs that will help remind people of the equipment that they should be using and the correct procedure for carrying out certain activities. We even have a number of signs that alert people to your various first aid locations.

To view our extensive range of health and safety signs, click here.

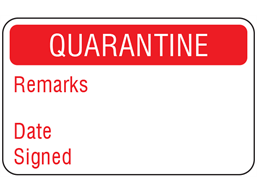

Quality Assurance Labels

Quality assurance testing is an essential activity that is carried out by laboratories worldwide to ensure that their products are produced to the highest standard possible. We have a huge range of quality assurance labels and tags on offer, and they are suitable for a range of applications throughout the production process.

We manufacture our quality assurance labels to an incredibly high standard, so you can be confident that whatever the situation or conditions that you require our labels to endure, they are more than up to the task.

If you would like to browse our comprehensive range of quality assurance labels, click here.

Quality Assurance Tapes

Not only do we supply an extensive range of quality assurance labels here at Label Source, we also stock a large number of quality assurance tapes. These tapes are manufactured with a strong adhesive bind that is ideal for packaging and product segregation.

We have a whole range of printed QA tapes including caution tapes, checked tapes, QC inspected, QC rejected, dispatch and handling tapes, and much more.

If you would like more information on our tapes, or are interested in viewing our complete range, please click here.

Here at Label Source, we aim to provide our customers with a truly comprehensive range of labels, tapes and signs. However, if you can't find the exact product you are looking for, please get in touch with our customer service team, who will be more than happy to help.