Our inspection label products have a new colour coding for 2017, together with the update on the inspection period covering 2017-2022.

The standard ranges continue to be available in the three sizes (15mm diameter, 25mm diameter and 40mm diameter), and are produced in either self-adhesive vinyl, or tamperproof destructible vinyl.

Besides, our standard parts we can supply similar products to your own customer specifications, which can have variable layout including company logos, to an extensive range of shapes and sizes. For a quotation please contact us on sales@labelsource.co.uk

It's essential that your equipment and tools are regularly inspected to ensure that they are in safe working order. However, when you're always busy working it can be difficult to remember when the next inspection is due. This is where we can help! Here at Label Source we stock a range of Next inspection Labels to remind you when a piece of equipment or tool needs to be inspected, so when that tool needs to be inspected, you can have it ready on the day. These labels come in a range of styles and can be pretty much applied to any surface.

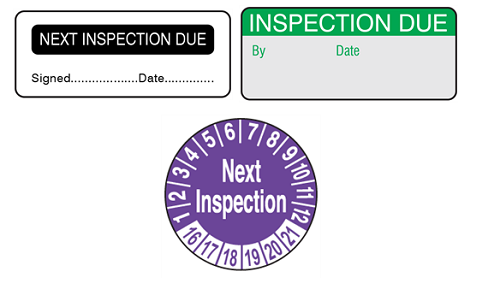

Here are some of the Next inspection labels we have to offer:

Next Inspection Due Label

Write on surface label

Material: Polyester, Self-Adhesive, Print receptive

Size: 20mm x 50mm

Supplied in packs of 100 labels

Inspection Due Aluminium Foil Labels

Material: Aluminium Foil, with self adhesive backing

Size: 16mm x 38mm

Supplied in rolls of 250 labels

Next inspection Due Month and Year Label

Material: Choice of Self Adhesive Vinyl or Tamperproof Self Adhesive Vinyl

Size: Diameter of 15mm, 25mm or 40mm

Supplied in packs of 250 labels

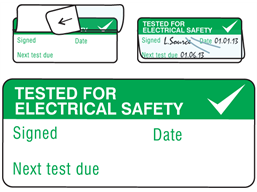

Tested for electrical safety, next test due write and seal labels

write and seal label

Scratch and Chemical resistant

Waterproof

Size: 16mm x 38mm

Material: Self adhesive vinyl, with part attached clear laminate

Supplied in rolls of 500 labels

If you wish to view our entire range of Next Inspection Labels, please click here.

It is sometimes difficult to quantify the cost of poor quality. Customer complaints, returned goods, lower productivity through re-working or new manufacture, and waste materials are just some of the elements to be considered.

Thus, QC inspection forms a vital function in detecting and preventing defects, in both products and processes, to provide corrective actions and for preventing defective goods being shipped to customers.

Not only does this fortify bottom line financial performance, but has a critical impact on; reduction of waste, scrap or pollution; lower maintenance costs; increase productivity and operator efficiency; and bolster staff motivation and morale.

Label Source supply a range of QC and QA labelling for marking products, and in identifying their quality status. These include our QC inspection ranges, Inspection labels and our Production status label ranges.

Label Source’s range of inspection labels continues to be popular for many quality assurance, test, service, calibration and maintenance applications. These are available in three sizes, 15mm diameter, 25mm diameter and 40mm diameter, making them suitable for marking equipment, instruments, appliances and machines, from small hand-held versions to larger fixed plant.

The inspection labels can be easily marked or punched to identify the month and year of the current or next required action, and can cover a six year cycle. The labels are available in self adhesive vinyl, and in security material, tamperproof vinyl, where warranty or guarantee integrity may be important.

Beside our standard ranges, we can manufacture to customer requirement, including company logos in a wide range of shapes and sizes. For further information contact Label Source by e-mail (sales@labelsource.co.uk) or by telephone (0800 3761693 in UK, or + 44 1443 842769 outside the UK).

One of the main health risks from contamination in engineering water systems is the bacterial infection Legionella. This bacteria can be transmitted through water vapour or mist and inhaled, hence leading to respiratory infections. The more severe cases are from Legionnaires disease, which can lead to pneumonia , and other secondary infections, which can lead to death. The milder forms are Pontiac fever, and Lochgilhead fever.

Legionella microorganisms flourish in temperatures of between 25°C and 45°C, particularly, if an abundance of nutrients such as sludge, sediment or rust reside in the water system. Structures at risk include cooling towers, air conditioning, hot and cold water systems, humidifiers, spa pools, hot tubs and Jacuzzis, decorative water fountains, dental equipment, ice making machines and dishwashers.

It is necessary that an assessment should be undertaken to prevent or control the risks of a Legionella outbreak. This can involve monitoring, inspecting, cleaning, disinfecting, flushing and sampling.

Label Source has supplied various labels to water system inspection companies and UKAS test laboratories to identify monitoring points, decontamination actions, safety procedures and inspection records. For further information on custom printed labels, signs and tags contact us by e-mail (sales@labelsource.co.uk) or by telephone (0800 3761693 in UK or +44 1443 842769 outside UK).