Many people have been seriously injured - or worse - while performing routine maintenance on machinery that should have been perfectly safe. Isolating your machines using the correct lockout procedures minimises the risk of unexpected start-ups while maintenance work is in progress, protecting the lives and wellbeing of those doing the work.

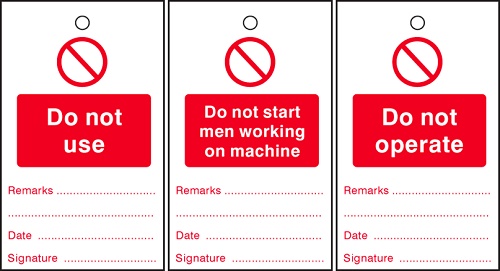

Here at Label Source, we sell a range of maintenance tags to help you identify machinery and equipment that, for safety purposes, should not be used. With clear instructions like 'Do not use' and 'Do not start - men working on machine', our maintenance tags are ideal for locking out heavy machinery during services and repairs (although we also stock labels that warn of high voltages, poisons, harmful gases, and other hazards).

In case you're not convinced of how important maintenance tags can be, here's just one example of what can happen when machines aren't properly 'tagged out' while maintenance work takes place. In November 2005, two men in Lanarkshire, Scotland were cleaning the inside of an animal feed mixer when the machine started up unexpectedly and killed them both. The HSE investigated this incident and found that it could have been "easily prevented" if the machine had been properly isolated:

"The process of isolation means establishing a break in the power supply, normally by using a lockable switch, and then securing the switch in the 'off' position using a padlock to prevent it being switched back on until the work is finished." - John Madden, HSE Inspector, speaking in 2008

Once you have completed the lockout process described above, it's important to use a maintenance tag to label the locked machinery and inform other workers that the machine is not to be used (most maintenance tags leave space to explain why the machine is locked out).

The incident you just read about resulted - full story here - in a total fine of £63,750 for the two companies involved, but far more importantly, it led to two deaths that could easily have been prevented. Click here to browse our maintenance tag range, and don't let the same thing happen on your watch!

Label Source supply an extensive range of labels for use in recording maintenance of equipment, plant and machinery, which are relevant for whichever type of maintenance system adopted. The ranges include our maintenance labels, maintenance tags, aluminium foil labels, write and seal labels, and equipment status labels and tags. Also, many others are produced to customer specification to include company information and inspection criteria.

So as part of your maintenance regime use these label and tag products to assist in safe maintenance practices for your workers and the environment, to provide lower process downtime through equipment failures, more efficient use of resources, and enhanced product quality.

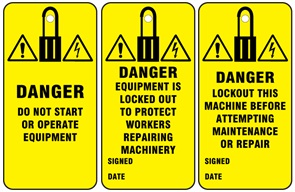

You may remember that, two weeks ago, we shared a series of upsetting stories about people who had been injured/mutilated by the machines they worked with. Well, if you want to avoid incidents like that on your premises, our lockout tags are the solution you need.

These highly-visible yellow tags can be attached to machinery and equipment to warn staff that the item in question is being serviced and may not be used until the tag has been removed by authorised personnel. This ensures that:

- Service personnel won't get trapped in moving parts when a machine starts unexpectedly

- The risk of electrocution and electric shock is kept to a minimum

- No equipment is damaged through improper use

Each of our lockout tags has a hole for easy attachment, and many of the tags give room for a signature and date, allowing authorised personnel to identify themselves when using the tags. Click here to see our full range of safety lockout products

We've told you before about the gruesome accidents that can occur when somebody is working on a machine and somebdoy else switches the machine on. Limbs and even lives have been lost because people sometimes don't think before activating potentially hazardous equipment.

Fortunately, there is a way to prevent accidents like this: maintenance tags! Service personnel can attach these semi-rigid plastic tags to the machines they're working on, letting everybody else know that those machines are not to be used until further notice.

Proper use of these labels can quite literally be a lifesaver. Far too many maintenance personnel have been killed by the machines they work on, and a number of these deaths might have been prevented if the maintenance work had been more clearly signposted. If, for example, you went home tonight and saw a 'Do Not Start - Men Working on Machine' tag on your oven, would you switch it on?

We sell a range of maintenance tags here at Label Source; each one gives clear instructions (e.g. 'Do Not Operate', 'Do Not Open Valve'), and some are designed to warn of more specific hazards, such as high voltages, poisonous gas, and asbestos dust.

Click here to see our full range of maintenance tags - they could save somebody's life!