Most label printers use thermal technology (heat) to print. However, you can use two different types of thermal printing: direct thermal printing and thermal transfer print.

So, what is thermal printing, and what are the differences between the different types?

What is Thermal Printing?

Thermal printing is a great alternative to laser and inkjet printing, as it requires less maintenance, has a lower cost, and prints almost instantly all while avoiding the bleeding you can get from other forms of printing.

You also, however, need to understand that thermal printing and thermal transfer printing are two different things.

What is Direct Thermal Printing?

Direct thermal printers apply heat to the paper, turning some parts of it black to form text or images (note that thermal printers use rolls of paper that are specifically designed for this purpose). Thermal printers are most commonly found in shops, where they are used to print customer receipts; since thermal printing requires no ink or toner, it's a cost-effective option.

Direct thermal printers typically have a good shelf life, but they’re not ideal for situations where the printed product will be exposed to sunlight or heat as they’re prone to fading.

In summary, direct thermal labelling is an ideal no-ink solution for labels that don’t need a long life.

What is Thermal Transfer Printing?

Labels that are created via direct thermal printing are not designed to last, and that’s where thermal transfer printing comes in.

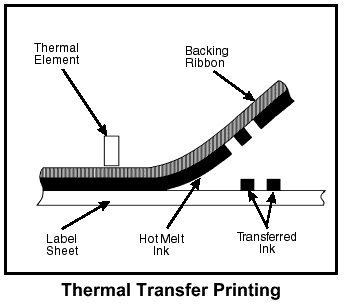

Instead of applying heat directly to the paper, thermal transfer printers apply heat to an ink ribbon, which then transfers ink onto the paper.

The downside, of course, is that you have to replenish your printer with a new ribbon from time to time. Still, if you are making labels for inventory, barcoding, or asset tagging, the extra expense is well worth it - thermal transfer labels last a lot longer than standard thermal labels, and they're far more scratch- and abrasion-resistant, too.

When using thermal transfer printing, you also have the benefit of being able to use different types of transfer ribbons that help you to achieve different results.

Thermal Transfers with Label Source

To Recap:

- Direct thermal labelsare cheap, but not suitable for long-term applications

- Thermal transfer labelsare far more durable and less prone to fading, making them great for long-term use

Now that you know how they work, click here to see our collection of thermal transfer labels and other consumables.

You can find all the safety signs, labels, and products you need here at Label Source. Start browsing or get in touch today to find out more.