Electrostatic shock is an everyday occurrence in multiple industries, especially if you work with electronics.

Electrostatic charge can lead to damage to delicate parts of electronics like chips and other small elements.

Static charge naturally builds up in most people and animals, so how can it be avoided? Below, we discuss what electrostatic is and how it can be negated, as well as how to eliminate electrostatic discharge in the workplace.

What is Electrostatic Force and Discharge?

Have you ever grabbed a shopping trolley, shaken someone’s hand or opened a door, just to be met with a small electric shock? Well, that is the build-up of electrostatic force and discharge in action. In people, it’s usually trivial, but it can have major effects on solid-state electronics.

Electrostatic force (or discharge) is defined as the sudden flow of electricity between two charged objects. Usually, this happens between human skin (which carries a positive charge) and synthetic materials (which carry a negative charge).

Over time, the electrostatic force on an electronic device can wear down its chips. This impacts how well the device functions. If the electrostatic force builds up, then a business could face costly (and avoidable) maintenance costs.

How to Eliminate Electrostatic Discharge

Eliminating electrostatic discharge is – thankfully – easy to do. There just needs to be a process in place where the person using an electronic device “grounds” themselves, thus removing the charge.

There are a few methods to do this, but in a work setting, we recommend using one of the following:

- Grounding mat

A grounding mat is simply somewhere where a worker stands before handling electronics. This grounds the user, removing the electrostatic charge.

- Specialised gloves

Using specialised rubber gloves can minimise the chance of electrostatic charge building up.

- Bonding plugs

Connects matting, wrist straps and other equipment to a common grounding point, removing the charge.

There are other more DIY methods, such as using a metal wire hanger or dryer sheets, but in a professional workplace, you need something with 100% effectiveness.

<h2>How Labels Help to Prevent Electrostatic Damage</h2>

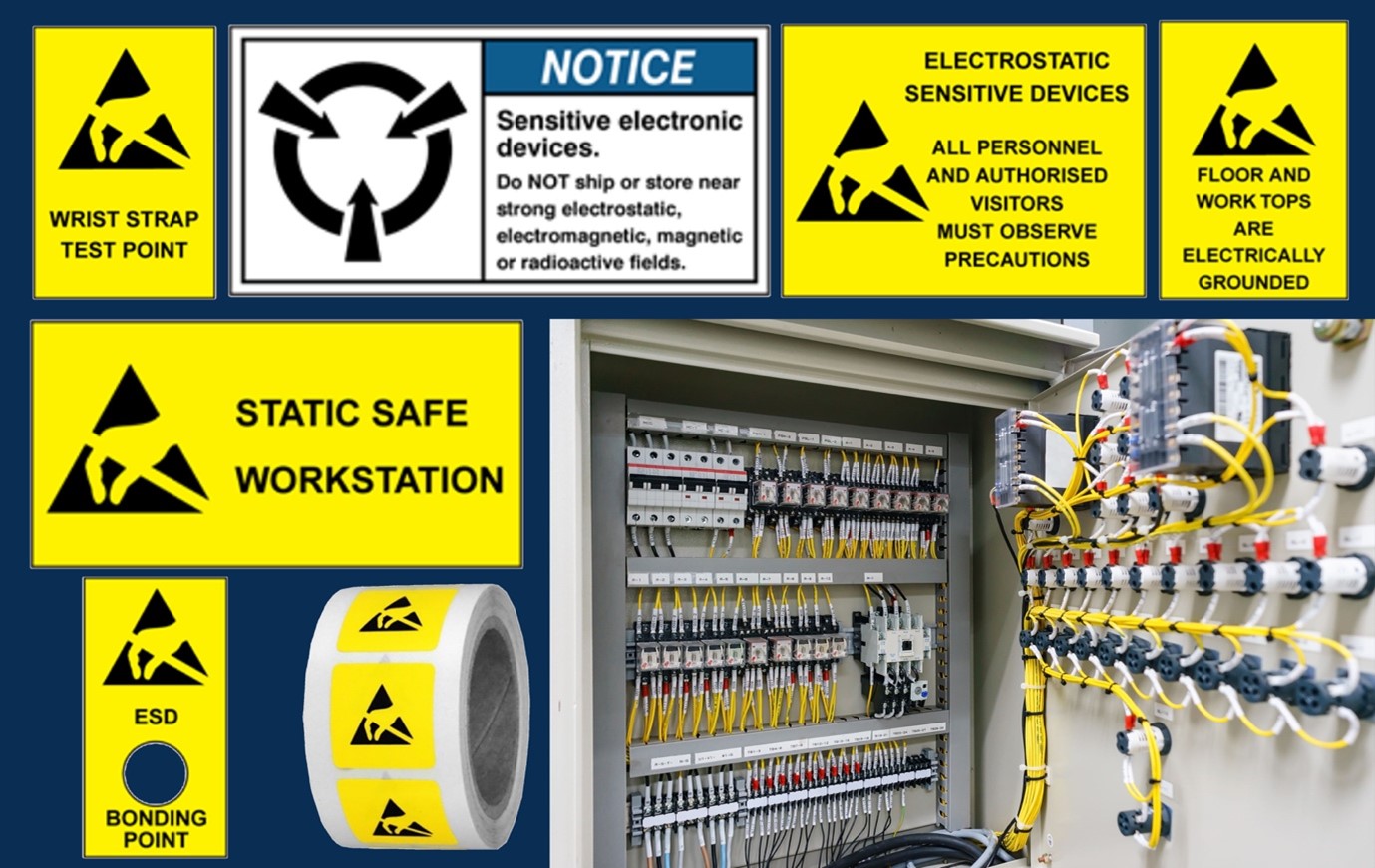

Labels have one primary role: reminding employees of the dangers of electrostatic force. By reminding employees to remove their charge, you can ensure the right steps are taken to keep electronics in good condition.

Labels need to be placed in Electrostatic Protected Areas (EPA) to identify grounding points and equipment. Without this, it’ll be difficult to put a proper process in place and, down the line, a busy worker will forget to ground themselves. Over time, this could rack up significant maintenance costs.

Get High-Quality Electrostatic Labels Today

To keep your equipment safe, we recommend investing in proper electrostatic processes and labels. These can save you and your business thousands in costly maintenance fees.

Get high-quality electrostatic labels today from Label Source. And for all the latest industry news, be sure to follow us on Twitter.