A week has gone by, and we have yet another story to bring to you of a firm being fined for poor safety procedures. It has been reported by WirralGlobe that Cammell Laird have been fined £400,000 for safety failings, after a worker suffered serious injuries whilst carrying out repair work at the Birkenhead shipyard. The 59-year-old from Ellesmere Port, Cheshire, sustained fractures and crush injuries to his right hand in the incident on July 20 last year, and the accident had made him unable work for 5 months, but has now returned.

The incident was investigated by the Health and Safet Executive (HSE) which prosecuted Cammell Laird Shiprepairers and Shipbuilders for serious safety failings. Liverpool Magistrates Court heard this week that the worker was repairing a lathe at the time of the incident. Whilst completing the repair he noticed that the shafts and couplings were dirty. In order to clean these components, he wrapped emery cloth around the lead screw and switched the lathe on. As the machine run, his right hand was pulled in to the moving parts, resulting in his hand being crushed.

A system of lock off, which would of prevented reconnection of the power to the machine, had been identified and was outlined in the written health and safety management system; however, it had not been properly communicated to employees or implemented. Cammell Laird pleaded guilty to breaching section 2(1) of the Health and Safety Work Act 1974 and were fined £400,000, and ordered to pay costs of £7,683.

Health and Safety should be a concern for any organisation. It is the responsibility of the business owner to ensure to carry out a thorough risk assessment and to ensure that all measures possible have been taken to minimise the risk of someone coming to harm at your workplace or as the result of your operations.

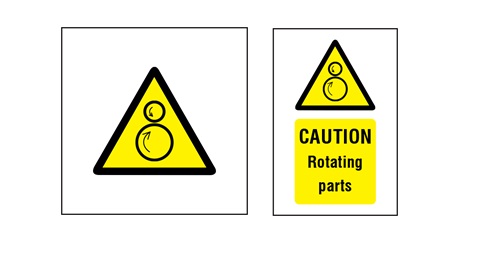

To ensure that a similar incident like this one doesn't happen to you, we stock a fantastic selection of Safety Lockout Labels & Signs, as well as a range of Moving Parts Warning Signs.

Our Rotating Parts Hazard Signs minimise the risk of injury in the workplace by ensuring you're aware of the dangers at work from machinery with rotating parts, these equipment include feed rollers, pulley drivers, cog wheels and V-belts, and the risks increase with projecting bolts, keys or screws. The injuries you may sustain could be the crushing of your finger, arm or body on contact, and even suffocation from tight wrapping of clothing or from sparks and flying parts. It's important that when using a machine with rotating parts that you are wearing no loose clothing, if you have long hair you must ensure its tied back and you must be aware of what you're doing at all times.

To reduce the risk of any injuries sustained whilst operating a machine with moving parts, we suggest that you have one of Rotating Parts Hazard Signs near the machine to ensure the operator that and any bystanders of the risk associated with that machine. Our hazard signs come in a range of sizes and come in either self-adhesive vinyl or rigid plastic. They also comply with BS 5378, Safety Signs and Signals Regulations 1996, and the Provision and Use of Work Equipment Regulations 1998.

Click here to browse our range of Rotating Parts Hazard Signs.