In order to protect employees and members of the public from harm, it is vitally important that chemical hazard labels are used by businesses who deal with potentially harmful chemicals.

Whatever the point of contact may be, it is paramount that the proper warnings are provided for substances which possess any of the following, hazardous qualities:

- Flammable, explosive or oxidising - Substances which present significant risks of when stored in certain conditions, or exposed to certain substances.

- Toxic - Substances which present a risk of contamination or poisoning.

- Corrosive - Chemicals such as acids, which are able to cause damage to human skin and other materials they come into contact with.

- Gases Under Pressure - Gases stored in compression containers, which present a risk of releasing the gas contained at a rapid rate if damaged.

& more, including irritants, and substances which may harm the environment.

In order to prevent damage and injury due to these risks, chemical hazard labels should be used at each point of potential contact, in order to ensure that the warnings are maintained at all times.

Chemical Hazard Labels should be used:

- In workplaces with hazardous chemicals present, such as laboratories and hospitals.

- On containers which are being used to store and transport hazardous goods.

- On vehicles which are used to transport potentially dangerous chemicals.

- During the production and packaging of substances.

If your business deals with potentially harmful chemicals, which have the ability to impact the health and well-being of those who may come into contact with them, then be sure to use chemical hazard labels and signs! These are needed to provide effective warnings of the risks connected with these substances, and instructions for dealing with the substances.

Our full selection of dangerous chemical labels has labels to suit a wide variety of purposes, and can be found here.

Here at Label Source, we aim to provide a flexible service that meets each and every customer's needs, whatever they may be. This means offering a huge variety of bespoke labelling options and enabling you to add your own corporate branding to our products, but it also means doing whatever we can to make the ordering process itself as smooth and as easy as possible for you.

We cater to a vast range of businesses and individuals in the UK, Europe, and even further afield. This has taught us that different customers in different countries tend to have different preferences at the checkout: some are content to simply enter their card details, while others require a pro forma invoice. Some are keen to complete the purchasing process as quickly as possible; others will take the time to register an account if it will make life easier next time around. And, of course, everyone works in different currencies depending on when they're based.

Our online store aims to cater to all of these contrasting requirements and preferences. When you place an order with labelsource.co.uk, you can:

- Choose to pay in pounds, euros, or US dollars

- Pay by credit or debit card (we accept most major card providers, including Visa, Mastercard and American Express)

- Use our pro forma order system and pay by bank transfer

- Register a Label Source account for easy repeat orders, or use our express checkout option if you're in a hurry

We're here to provide the perfect solution to your organisation's tagging, labelling and signage needs. Click here to return to our homepage and begin shopping, or contact us today if you have any questions for the Label Source team.

An engineering firm in Hampshire has been fined £14 thousand (plus costs) over an incident that left one worker with a severed finger.

Pictured: 'WARNING: Keep hands clear. Moving parts.' safety label

Repro Engineering of Waterlooville (roughly 8 miles from Portsmouth) were ordered to pay up after an HSE inquiry concluded that the injury "could have been prevented by more active and robust management action". The incident in question occurred back in July 2015: the worker was trying to fix a jam in the lathe he was using when his hand came into contact with the machine's moving parts. He ended up losing a finger as a result.

This case was heard at Portsmouth Magistrates' Court, and Repro Engineering plead guilty to breaching Provision and Use of Work Equipment Regulations 1998*. Their primary offence was allowing access to the machine's moving parts while it was in operation, a very unsafe practice that sadly resulted in a rather gruesome accident.

Moving machine parts can be extremely dangerous, and this is why it's important to nurture safe working practices within any environment where they are present. Here at Label Source, we stock a variety of products that can help to prevent moving part accidents and remind workers of the risks associated with them:

*Specifically Regulation 11(1), which decrees that "every employer shall ensure that measures are taken...to prevent access to any dangerous part of machinery or to any rotating stock-bar [or] to stop the movement of any dangerous part of machinery or rotating stock-bar before any part of a person enters a danger zone".

Source: LRB Consulting

Heavy Lifting can be very hazardous to your workforce if done incorrectly. If you lift a heavy object carelessly you could end up pulling muscles or you could even suffer long-term damage to your back or upper limbs. 75% of injuries caused by manual lifting can be avoided if workers have been trained and shown how to lift safely. Here at Label Source we have a range of Manual Lifting Safety Signs that help to educate workers and minimise the risk of accidents and injuries in the workplace.

All of our lifting safety signs will help your workers comply with the Manual Handling Operations Regulations 1992, which refer to the lifting, lowering, carrying, pushing, pulling, or supporting of heavy loads. Our range of manual lifting signs reminds employees to follow correct procedures when they're lifting heavy loads. Some of these procedures are correct lifting, seeking assistance where appropriate and following correct lifting guidelines. Failing these regulations could result in severe injuries, as well as damaged goods if these loads are dropped.

Here are a few examples of the Manual Lifting Safety Signs we supply here at Label Source:

Two Person Lifting is required

These are two person lifting safety signs inform workers when they should require assistance to lift a load due to it being either to heavy or awkward for one individual to carry. These labels come in packs of 100 and are made from self-adhesive vinyl with a clear polyester laminate. These labels are available in two sizes - 25mm x 50mm or 50mm x 100mm - are waterproof, chemical and abrasion resistant.

Lift Correctly Symbol and Text Safety Sign

This safety sign reminds workers to adopt a safe lifting technique, to prevent any injuries or accidents from happening. This safety sign is available in two sizes - 150mm x 100mm or 300mm x 200mm - as well as a choice of two materials - Rigid Plastic or self-adhesive vinyl. This safety sign complies with ISO EN 7010 and Safety signs and signals regulations 1996.

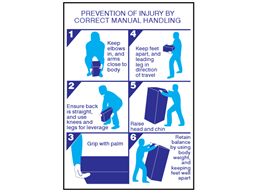

Prevention of Injury by Correct Manual Handling Safety Sign

This safety sign prevents workers from getting injured by outlining what the correct posture is when lifting parcels, packages or other heavy items. This safety sign is only available in rigid plastic but there is a choice of two sizes - 300mm x 200mm or 600mm x 400mm. This safety sign complies with the Manual Handling Operations Regulations 1992, ISO 7010 and Signs and Signals Regulations 1996.

Click here to browse our full range of Manual Lifting Safety Signs

A few days ago it emerged that G4S Cash Solutions has been fined £1.8 million for failing to protect its workers from legionnaires' disease. Harlow Council took action in October 2013, following reports that a worker had contracted the serious lung infection which causes flu-like symptoms.

Town Hall's environmental health officers were unable to prove that the Harlow worker had contracted the disease through the site. However, searches uncovered that there was a serious lack of compliance in maintaining water systems at the workplace.

Harlow Council began prosecution proceedings and G4S pled guilty to two charges under the 1974 Health and Safety at Work Act on June 20. At their sentencing the court judge fined the company and the company have told the court that they have taken a number of measures to improve the health and safety of their site.

The bacterial infection Legionella is one of the main risks of contamination in engineering water systems. The most severe cases are from Legionnaires disease, which can lead to Pneumonia, and other secondary infections, which could lead to death. The infection flourishes in temperatures of between 25°C and 45°C, particularly, if an abundance of nutrients such as sludge, sediment or rust in the water systems and it affects a range of structures such as air condition systems, cooling towers, hot and cold water systems and many more.

It is vitally important that an assessment should be undertaken to prevent and control the risk of a legionella outbreak. This can involve monitoring, inspecting, cleaning, disinfecting, flushing and sampling.

Label Source has supplied various labels to water system inspection companies and UKAS test laboratories to identify monitoring points, decontamination actions, safety procedures and inspection records. For further information on what custom printed labels, sign and tags we could offer you, contact us by email (sales@labelsource.co.uk) or by telephone(0800 3761693 in UK or +44 1443 842769 if you're outside the UK).