Airborne contaminants are part and parcel of industrial work. Before the advent of health & safety, illness and death from exposure to these particulates were seen as an unavoidable consequence. In modern times, though, a number of measures have been put in place to stagger the effects of damaging inhalation. While safety equipment like masks helps, the most ideal solution is to remove the hazard at the source – this process is known as local exhaust ventilation.

LEV is now commonplace in most industry controls. Below, we answer the question of “what is local exhaust ventilation”, as well as listing its importance and how our LEV labels can help.

What is Local Exhaust Ventilation?

Local exhaust ventilation (LEV) is defined by the Health and Safety Authority as “an engineering system to protect employees from exposure to hazardous substances by containing or capturing them locally, at the emission point”. By removing the hazard at the source, worker protection is maintained with the added advantage of requiring less air and resources as general ventilation systems.

LEV systems tend to differ on a case-by-case basis, but, generally, they possess the following elements:

- Hood – the place where contaminant air enters the system and is funnelled to the next stage in the system.

- Ducting – designed to funnel the contaminated air to the air cleaner quickly and safely.

- Air cleaner – cleans and filters the air.

- Air mover – a fan which moves the air through the system.

- Discharge – removes air to a safe place, usually externally.

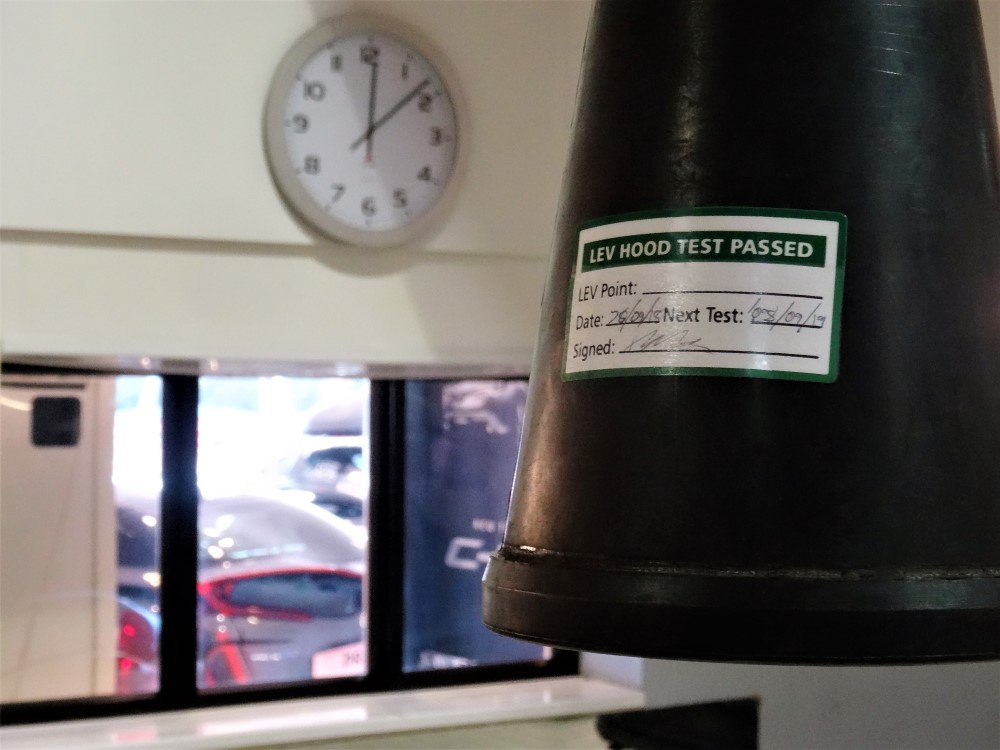

And, of course, this is labelled with an LEV sticker to show test records for their safe and efficient operation.

All areas of the LEV system are equally important to its success, but the hood needs to be perfect. If the hood is poorly designed or is incompatible with the air, then workers will be put in immediate danger.

The most common errors in an LEV system comes from the hood, so it needs to be designed with the type of contaminated air and a focus on facilitating diffusion in mind. Typically, hoods come in three designs:

- Enclosing

- Captor

- Receiving

Each hood type has its own niche within an LEV system. Using an incorrect or ill-fitting type will render the entire process useless.

As with any other industrial system, LEV must be regularly tested with a clear, legible visual test label.

Importance of an LEV System

Air pollution can be a major problem if you’re exposed to it on a regular basis. For example, asthmagens are common in industrial workplaces. These are substances that can make your airways more sensitive and lead to the development of asthma – this is but one example of the life-changing effects poor air ventilation can have on a workforce.

Other knock-on effects have recently been discovered, including the possibility of poor air quality negatively impacting women’s fertility.

The long list of negative effects means lawsuits against employers regarding the issue are not uncommon. For example, in June, a Dorset-based firefighter received compensation after a successful lawsuit against defence company QinetiQ. The firefighter’s existing lung condition was worsened following exposure to diesel fumes at the company’s fire station.

Trucks would drive in and out of the airfield’s garage which was unventilated. The diesel fumes, then, had no way to escape. QintetiQ later installed an LEV system, but since this wasn’t installed since the garage’s construction, the firefighter was awarded compensation. If this was in place, then the firefighter and his fellow employees based in the garage would have been protected.

Therefore, businesses must make every effort to prevent exposure to poor air quality. Exposure routes are defined by the HSE as:

- Breathing fumes, dust, gas or mist.

- Skin contact.

- Injection into skin.

- Swallowing

While LEV cannot help against the last three, it is the best method for protecting against inhalation. That’s why it’s a mainstay in schools, laboratories and workshops.

Stay Safe with LEV Labels

Label Source has stocked the best in local exhaust ventilation labels for verification of safety. For more from the ever-changing world of labels, be sure to follow Label Source on Facebook and Twitter.